Minnesota

South Dakota

Iowa

North Dakota

Eastern Wisconsin

Western Wisconsin

Is Your Plant Effectively Managing the Risks

Associated with Mist in its Processes?

Authorized Distributor & Service Provider for Donaldson Torit®

What is determined as mist? In manufacturing environments, applications that use oil and water-soluble lubricants, coolants, and detergents can generate mist (liquid particles 20 microns or smaller) and require the control of a mist collector. Applications include metal cutting, metal forming, metal grinding, part washers, and lube oil systems.

Metalworking fluids (MWF) are a key component in today’s manufacturing process; however, they can present several workplace hazards. Specifically, they generate airborne mists that must be handled properly to protect the health and safety of employees.

For over half a century, manufacturers of metal products have been installing mist collectors for preventive maintenance on their mills, drills, lathes, grinding, casting, and other cutting, forming, and related machines.

Over the years, demand has grown for higher-quality parts with tighter tolerances turned out quicker and at a lower cost. This has increased the speed of the machining tools, the number of coolants and lubricants, and the pressure at which coolants and lubricants are delivered. These increases have significantly impacted the amount of mist generated while decreasing the particle size. The results of all this are decreasing air quality, requiring new controls to reduce airborne mist levels.

P-A Industrial Services (PAIS) has got you covered at every stage, from the design and installation to the repair and maintenance of your industrial mist collection system.

Optimizer Preventative Maintenance & Remote Monitoring Program

With our Optimizer Preventative Maintenance & Remote Monitoring Program, PAIS can work with you to maintain an effective industrial mist collection system. Uncollected mist can leave condensation and residue on floors, machines, and other locations to create unsafe and unclean conditions for your employees. This program’s key benefits include clean air for your working environment, enhanced system efficiencies for future cost savings, and so much more.

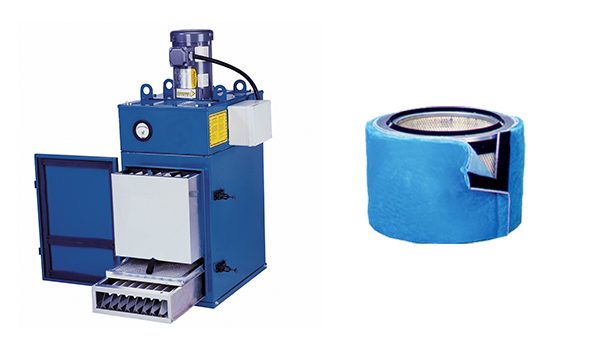

Mist Collector Filters

PAIS can provide you with high-quality replacement filters and mist collector filter changes for all of your equipment. Selecting the right filters helps to increase manufacturing efficiencies, provide a clean environment for employees, and improve overall system performance. We’re pleased to offer advanced mist collector filters such as the Donaldson Torit Dryflo® cartridge filter featuring a proprietary blend of synthetic fibers that reduces pressure drop and increases airflow, the Donaldson Torit WSO cartridge filter featuring Synteq XP™ technology that improves efficiency and filter life, and many other replacement mist collector filters to meet your needs.

Services Offered & Supported Manufacturers

We specialize in the following services:

- Donaldson Dust Collection/Baghouse Equipment

- Dust Collector/Baghouse Preventative Maintenance Programs

- Industrial Fan/Blower Preventative Maintenance Programs

- Fan Balancing and Vibration Analysis

- Installations

- Parts Supply

- Compressed Air

- Dust Collector/Baghouse Service

- Dust Collector/Baghouse Filters

- Filter Replacement Services

- Dust Collector/Baghouse Parts

- Dust Collector/Baghouse Installation and Design

- Airflow Measurement and Balancing

- Ventilation and Ductwork Design

- Combustible Dust NFPA 652

- Pneumatic Conveying Preventative Maintenance and Repair

- Accurate Service Documentation and Maintenance Records

We provide authorized parts and services for the following brands:

- Donaldson Torit (Donaldson Authorized Service Provider)

- New York Blower

- Coperion K-Tron

- Sweco

- Flexicon

- Quadro

- TerraSource Global

- Thermo Scientific

- Ametek

- Auburn International

- IEP Technologies

- Nilfisk

- Schenk Process MAC

- Camfil Farr

- Imperial Systems

- ACT

- AAF

- Aercology

- Airflow Systems

- Clemco

- Environmental Systems Designs

- Farr

- Geoff

- MAC

- Micro Air

- Nordson

- Pneumafil

- Robovent

- Steelcraft

- Trion

- UAS

- Wheelabrator

- AZO

- Buhler

- Carter Day

- DCE

- Flex-Kleen

- Golfetto

- Kice

- MAC

- MikroPul

- Murphy

- Pneumafil

- Steelcraft

- Wheelabrator

- Many more

?

Have Questions or

Need a Quote?

We’ll Help You Every Step of the Way.

Why Work with P-A Industrial Services?

We bring over 100 years of combined industry experience to offer top-rated services, parts, and equipment for all of your dust, mist, and fume collection systems, industrial fans, and compressed air systems. We utilize our unique total system approach to ensure that each component works at maximum efficiency with minimal downtime.